Here is a basic review of wood cribbing capacities and then some thoughts on how to increase your crews critical thinking before the heavy rescue lifting call.

Are you prepared to lift a heavy vehicle off of an entrapped victim? Do you have the knowledge, equipment, and cribbing to make the rescue fast and safe? Fast is a relative term in this case. Technical rescues are not often fast, but we should strive for expeditious rescue with coordinated and competent techniques.

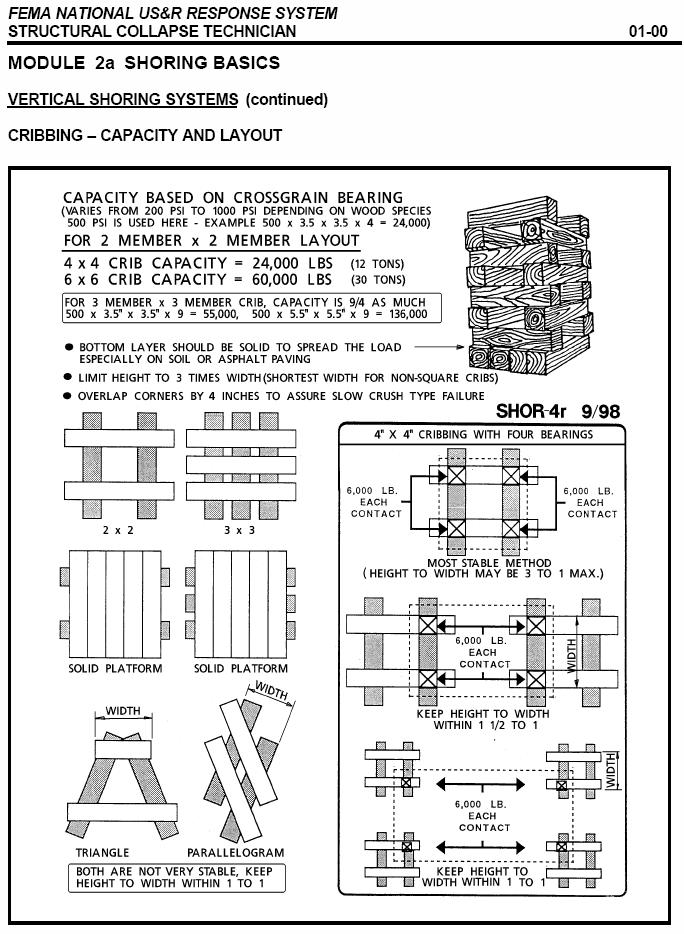

Remember a solid layer of blocks is always needed on the top for the airbags. A discussion on airbag capabilities, restrictions, and placement is in the works, stay tuned for that. A solid layer of blocks is recommended on the bottom when the ground surface is less than ideal, for example; soil, asphalt, stone.

One of our challenges is determining the weight of the load we are lifting and then selecting the correct cribbing technique to use. To increase your knowledge on commercial vehicle weights start in your firehouse with a quiz about the gross vehicle weight rating (GVWR) of each apparatus. Here’s what I found: ambulance = 15,000, engine = 25,000, tanker = 60,000, ladder = 72,000.

To expand on that, Phil Burden gave his crews in South Carolina a scenario where he drove a 1,500 gallon tanker up on the legs of a dummy. They discussed the options to get the dummy out, estimated they would be lifting 15,000-20,000 lbs., and successfully cribbed under and lifted under the transfer case of the rear axle to free the dummy. This is awesome in-house training.

Now, what about other commercial vehicles on the road. What are those weights? I certainly won’t be able to cover them all here, however, here are a few to get you thinking about the necessary cribbing techniques that will be needed when you roll up on a heavy lifting incident.

10 yard cement mixer – GVWR 68,000. Empty weight = 28,000. BIG difference. *Realize the mixer hopper is held in by gravity creating another stabilization hazard.

Garbage trucks similar to this size have a GVWR of 48,000 lbs. Larger trucks are on the road. Also consider a rainy day. Are they overloaded when full with wet material?

Pass it on!

First Due Tackle Pass It On – Firefighter, Rescue & Extrication Training

First Due Tackle Pass It On – Firefighter, Rescue & Extrication Training