This morning I was taking some pictures at the local school bus garage in preparation for FDIC and a straight truck tanker rolled in. So, of course I had to ask the driver (Russ, a firefighter from a neighboring jurisdiction) a few questions.

This morning I was taking some pictures at the local school bus garage in preparation for FDIC and a straight truck tanker rolled in. So, of course I had to ask the driver (Russ, a firefighter from a neighboring jurisdiction) a few questions.

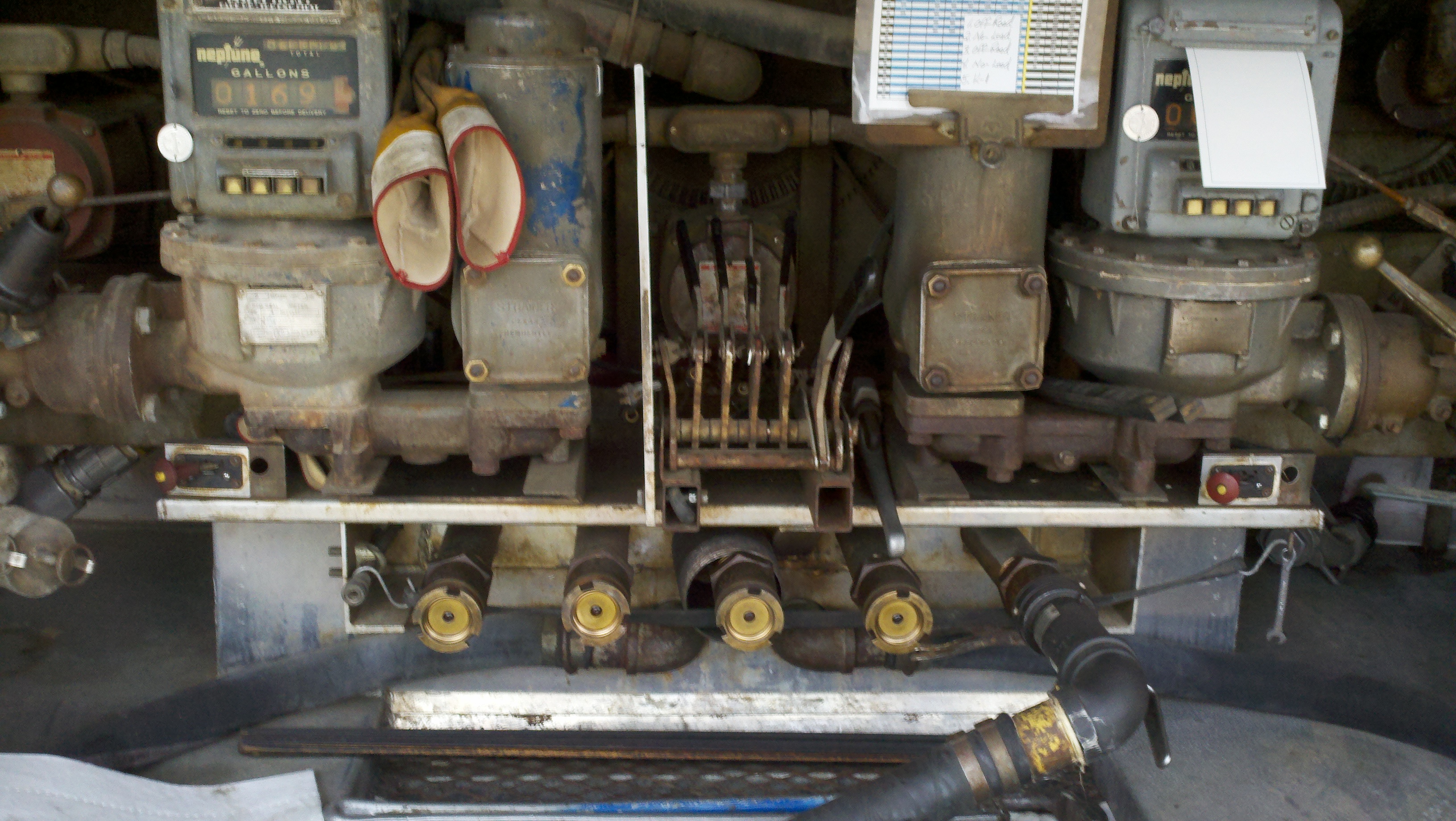

- Where are the valves to shut material flow off from the tank?

- How many different materials can this truck haul?

These questions led to a few other discussion points. The pictures and captions below sum up some valuable information that we can use.

The tank is a single layer, so any penetration will cause a leak. On this picture you will notice rib lines. The rib lines that are about the width of a letter apart from each other show where an air void space is location. The wider areas are the 5 separate tanks. If a tank gets an internal wall leak in it, fluid will run down and drip out a hole in the bottom of the void space.

This picture shows the top of each vessel. In the event of a roll-over, these hatches could easily be opened causing a significant spill. No pins or locks really secured the top hatch.

Here’s another drill idea: Gasoline Tanker – Company Drill. Most of the drivers of these rigs will give you a few minutes of training. Just ask.

Pass it on!

First Due Tackle Pass It On – Firefighter, Rescue & Extrication Training

First Due Tackle Pass It On – Firefighter, Rescue & Extrication Training